Huafu Chemicals is a factory specializing in the production of food-grade melamine tableware raw material. The melamine powder and melamine glazing powder produced by Huafu Chemicals are 100% pure and have good fluidity, which is very suitable for making various food contact tableware and utensils.

Therefore, the safety aspects of food contact materials that everyone is concerned about, and what specific tests need to be done, let’s take a closer look today.

Background Introduction

In recent years, the quality and safety of food contact materials has been concerned by countries all over the world, and major trading countries have introduced increasingly stringent laws and regulations and improved supervision mechanisms to eliminate hidden quality hazards and strengthen the safety management of food contact materials.

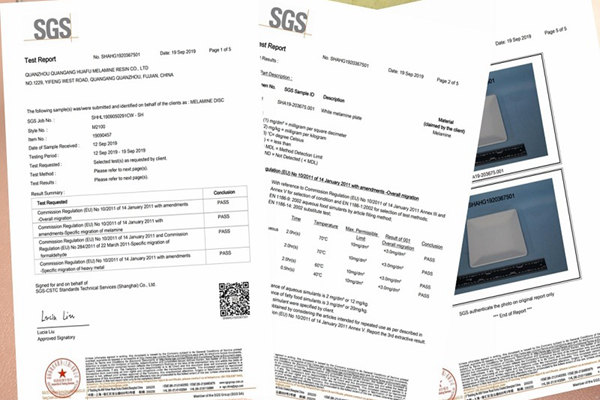

2019 test report of melamine disc made from Huafu Melamine Powder

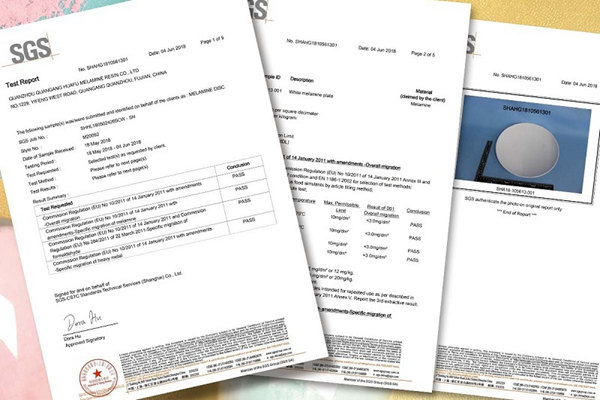

SGS

As an internationally recognized inspection, identification, testing and certification organization, SGS is very authoritative in the safety testing of food contact materials.

According to the characteristics of laws and regulations on food contact materials formulated by different countries and regions around the world, the global food contact material safety requirements are roughly divided into three regions: Asia, Europe, and the United States.

1. United States Region USA

Involved

US FOOD GRADE: U.S. FDA CFR 21 PART 175-189&FDA CPG 7117.05, 06, 07.

Test items

Organic coating requirements, paper product requirements, wood requirements, ABS plastic requirements, food container sealing ring requirements, melamine resin requirements, nylon plastic requirements, PP, PE plastic requirements, PC plastic requirements, PET plastic requirements, PS plastic Requirements, polyfeng resin requirements, etc.

US FDA's general requirements for food contact containers and materials

2. California 65

Test items

California 65 additional requirements for ceramics and glass products

3. European region EU

Test items

Plastic, organic coating, silica gel, rubber, paper products, metal, wood products, ceramics, glass, enamel.

4.Germany, France, and Italy have additional requirements for food grade relevant regulation

5. Chinese market

Test items

2018 test report of melamine plate made from Huafu Melamine Powder